Ornamental plant growers in Alabama feeling the squeeze of a competitive labor market may soon find help in an unexpected form. An AI-powered robot, currently in development at Auburn, will be able to inventory thousands of plants while also collecting data on plant growth, pests and diseases.

A team of researchers from the Alabama Agricultural Experiment Station was recently awarded $300,000 by the National Institute of Food and Agriculture to develop the robot. The project addresses a major issue faced by growers: the inefficiency of having humans manually count tens of thousands of plants each season.

“Right now, growers have to send a whole bunch of people down to physically count plants, and that’s not the best use of labor hours,” said Tanzeel Rehman, assistant professor and director of the grant project. “Inventory is one of growers’ main pain points.”

An ornamental nursery might have as many as 80,000 plants per acre, with larger nurseries covering more than 600 acres. Some growers estimate they spend more than $6.5 million in labor each year simply counting plants, according to Rehman’s research.

Growers need an accurate inventory before they can commit to fulfilling a major order, requiring workers to stop and take inventory. Growers also struggle with rising labor costs and immigration issues, which have threatened their profitability in recent years, according to Rehman. This is where the robot will help by speeding the sales process and making growers less reliant on labor for basic tasks like inventory.

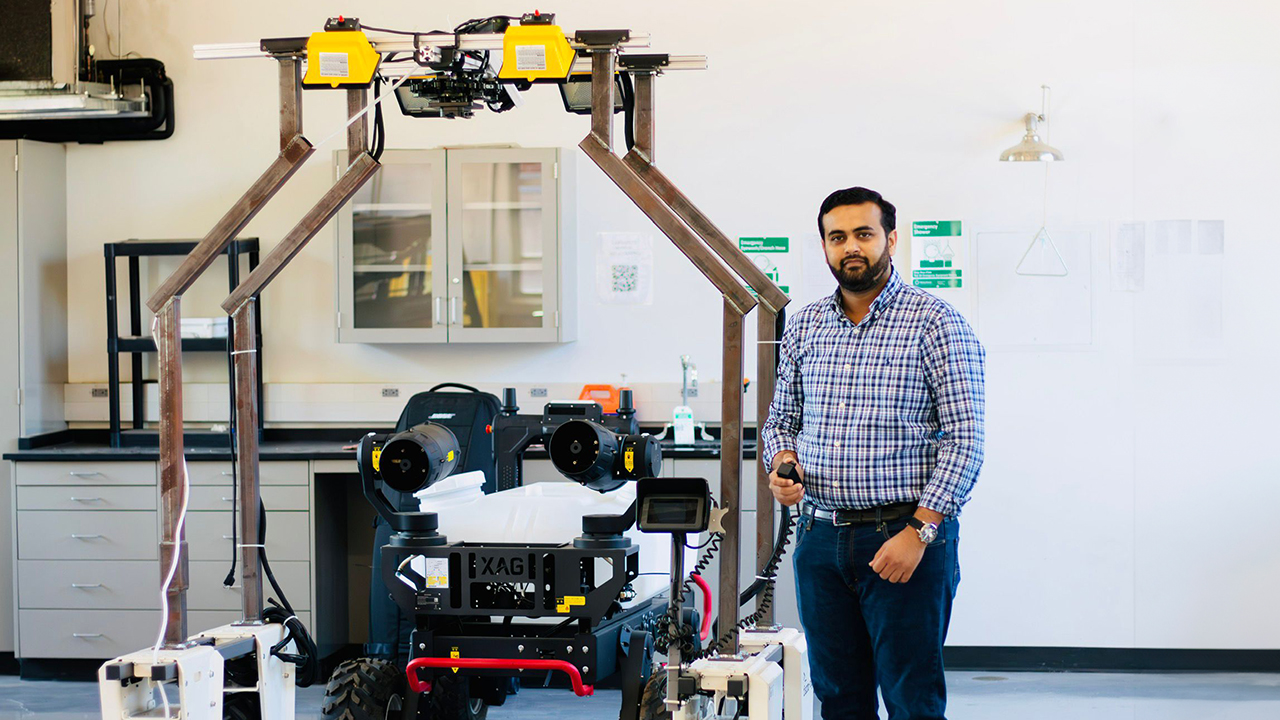

The robot, which somewhat resembles a Mars rover, straddles a row of plants as it moves. An array of cameras captures images of plants as they pass beneath.

The robot is being developed with the help of Alabama’s ornamental nurseries. Rehman and his team have spent days in the field gathering data to help the robot inventory and assess if a plant is ready for sale. The team interviewed nursery workers to learn just what makes a plant ready for sale — factors like shape, color, size and fullness.

“A robot can’t just say, ‘This plant looks good,’” said Rehman. “You have to teach it.”

To teach the robot, Rehman uses a kind of AI and machine learning called Deep Learning. “Deep Learning is an end-to-end AI where you feed data in on one side, which is the image,” Rehman explained. “And you get whatever you want to get on the other end.”

This process, though technologically advanced, requires researchers to painstakingly label images. By manually coding images with information as basic as “plant” or “not plant,” researchers are providing the AI with the data it needs to begin learning.

However, the robot, with its Deep Learning capacity, can provide growers with more than just inventory numbers. As the robot learns, it will be able to determine the size, grade and species of a plant. Using geolocation, the robot will also be able to tell which parts of a nursery have pests or diseases, allowing growers to administer insecticide and fertilizers more strategically.

Over successive seasons of use, the data collected will even show how plants grow faster or slower in different parts of the nursery and where diseases are most common. Meaning, the robot’s inventory data can be used for better, more efficient management of the nursery.

The research team opted to use an existing robot as well as existing sensors and cameras to keep the cost of the robot down. Rehman expects the robot will cost less than $20,000 when first commercially available to growers.

“It’s kind of the right time,” Rehman said, referring to the widespread availability of the technology. The team’s efforts focus more on adapting existing technology — robots, cameras and Deep Learning systems — to the ornamental horticulture industry, rather than inventing new robots.

As an assistant professor of smart horticultural systems engineering, Rehman is well suited for this project, which he hatched while still in graduate school. His position at Auburn is a joint appointment between the Department of Biosystems Engineering and the Department of Horticulture. This position was created in 2021 at the urging of Alabama’s ornamental horticulture industry, which recognized the role technology could play in advancing their industry.

The grant team also includes Jeremy Pickens of the Department of Horticulture.

The first commercially available version of the robot will likely be available August 2026. Teaching a robot takes time. Rehman and his team must collect data continuously across a growing season so the robot can recognize the same type of plant at any age from one month old to 12 months old. This requires repeatedly collecting images of the plants as they grow.

The current version is also limited to the two most popular and profitable types of ornamentals grown in Alabama: azaleas and hydrangeas. On a future grant, however, Rehman envisions the robot programmed with numerous species. He also expects it will be automated, able to run itself up and down the rows counting and collecting data without any human assistance.